As I sat around a campfire on St James Station in the Southern Alps of New Zealand, marvelling at the starry sky and thinking about some of the great hunting and fishing adventures I've had, I couldn’t help but think about how the hunting seasons have changed over the last 25 years. In such a short amount of time, the weather and temperature ranges we are operating in have changed significantly and this has affected fishing and hunting patterns dramatically. It is clear that the significant changes happening in our environment are caused by how we as humans are living and consuming.

At Evolve Outdoors, our goal is to make high performance, long lasting outdoor gear while reducing the negative impact on the environment as much as possible. In 2017 we launched our Sustainability Promise, in which Evolve commits to integrate sustainable practices throughout the entire company.

We are a company based in New Zealand which is known as a clean, green part of the world. Our product manufacturing is done overseas in Asia, USA, and Europe. Whilst travelling to these locations we noticed the very different levels of pollution. In China, during winter the air can be so thick with pollution that you can barely see 100m ahead. We started thinking about how terrible it is that as an outdoor brand we are manufacturing our products in such a polluted part of the world and thus contributing to this destructive mess. We, like you, have a passion for the wild and like to think we do what we can to minimise our impact on the environment. Being able to hand the outdoor traditions down to our future generations is extremely important to us.

In November 2016 we began a 12 month review process. This review investigated the impact we have on the environment at every stage of our product lifecycle. We delved into all areas of the company, right through to our factories supply lines, their supplier's supply lines, and the raw materials that go into our products, in order to estimate our overall waste footprint. From there we looked at what could be done to become an environmentally friendlier, more sustainable company.

During this review, we found some pretty nasty things; things we are quite ashamed of, but are not hiding from. Now that we are fully aware of these issues, we are able to turn these negatives around and contribute to the environment in a positive way. However, we have found that the price of being environmentally and socially responsible is significantly more than the industry standard. We also found the design time increases as more care has to be taken to ensure that we are doing things the sustainable way.

We had to make some pretty tough decisions as to whether we could support these increased costs and additional design times. But when push came to shove, the vote at Evolve was unanimous for doing everything we could to reduce our social and environmental impact. The cause is bigger than us as a company.

As a result, you as a consumer know that when you are purchasing Evolve gear, you will be paying slightly more for a product that will perform to the highest standard but you are also supporting brands that are doing their utmost to have the smallest social and environmental footprint in the industry.

I would like to thank my team for supporting the company-wide initiative that we are all hoping will become an industry-wide initiative. We are continuing to review our supply lines at a great depth and as we develop new products to replace existing items, we are becoming more socially responsible and sustainable. Check out each of our Sustainability Promise initiatives below.

- ROBERT WILSON | EVOLVE OUTDOORS FOUNDER

Our goal at Evolve Outdoors is to be innovative and create outdoor gear that is of unprecedented quality. While doing this we want to remain socially and environmentally aware.

Every product is driven by innovation and utilises cutting edge technology, design and production, to create incomparable comfort, performance and durability. Our emphasis on social and environmental awareness requires that each stage of our product lifecycle be analysed from the design phase, through to production, and eventually product disposal after years of use.

When considering new products, we put a lot of time into evaluating the the recyclability and potential impact of each material required. We also take an in depth look at our supply chains to ensure that each supplier meets our sustainability requirements.

A critical requirement is that we reduce the amount of waste that gets sent to landfills and where possible, maximise the amount of degradable and recyclable materials used in our packaging and the products themselves.

In early 2020 we have started making our clothing with fibers made from recycled plastics. This process directly removes waste plastics from ending up in landfill and dramatically reduces carbon pollution. For the full story check out our section Recycled Fabric section below.

OUR PRODUCTION AND SUSTAINABILTY PHILOSOPHY CAN BE SUMMARISED AS:

We strive to achieve end to end recyclability, where our products and packaging are sourced from recycled materials and can be 100% recycled at the end of their life.

We try to use processes that are as gentle on the environment as possible and that minimise consumption of water, chemicals and energy. This includes using suppliers who meet these requirements also.

We make products that last longer. This is better and more affordable for our customers who do not need to replace items as often, and also results in less waste in our landfills so is better for our environment.

We put a significant amount of time into our product design to ensure we have well thought out patterns and construction to minimise raw material wastage.

Social responsibility comes above profits!

In 2018 we strategised to reduce our consumption and use of plastic and cardboard packaging to prevent creating 3 Tonne's of waste by the end of December 2018. By June 2020, the total saved amounted to over 14 tonnes of waste damaging our environment.

We have now implemented Project ZERO. An immediate impact strategy where we have drawn a line in the sand and set a goal to prevent approximately 25 Tonnes of packing waste from going to landfill by 2025. With the support of all of you choosing our products, we hope to be able to smash this goal and be well soon on our way to being carbon neutral by 2030. We no longer follow the standard production and packaging methods to make this a reality. Let’s put a stop to not only tonnes of new plastic and cardboard being produced, but also ending up as waste and entering our oceans and landfills.

NASTY PLASTIC BAGS

Previously, every Evolve Outdoors product came individually wrapped in a plastic bag for protection and storage. Researching plastic bags and how long it takes them to break-down, or in reality not break-down, resulted in us becoming very concerned about our environmental impact. The polypropylene (PP) bags used to wrap clothing can take up to a thousand years to fully decompose.

There is no way to properly limit the effects of these plastic bags on the environment because the bags are not able to be reused or recycled effectively and there is no disposal method available that will fully eliminate the problem. The PP bags will either be burned or will end up in landfills. Both options are damaging to the environment. Burning the bags releases harmful toxins into the atmosphere and filling up landfills across the globe is unsustainable and is a short-term solution with long-term effects.

Even when these plastic bags are taken to landfills, they are easily caught by the wind and escape, ending up in our forests, rivers, and seas.This has a devastating impact on wildlife as avian and marine animals can easily mistake the bag for food, inhaling the bag causing suffocation.

The most significant action we can take at Evolve, to reduce our damaging footprint, is to get rid of these plastic bags. To eliminate the plastic that wrapped each product we have changed how the products are folded and instead wrapped each product with recycled paper which is then able to be recycled again after its use. The branding on our paper is printed with vegetable-based inks which allows the paper to decompose quicker if it does go to landfills or if you choose to put it in your compost.

CARDBOARD BOXES AND SWINGTAGS

Every year we use approximately three tonnes of cardboard in our packaging. We therefore have an opportunity to make a meaningful difference to our environmental footprint by reducing the amount of card we send to landfills.

Firstly we chose to sacrifice the more polished look by using recycled card and vegetable-based inks. Also, after much research, we found that our current shoe box design made the boxes unrecyclable due to the glue involved. By thinking smarter and designing a box that avoids the use of glue, our shoe boxes are now 100% recyclable. While all our packaging is now made from recyclable materials and can easily be recycled, if it does find its way into landfills it will decompose quickly with no adverse effects. If you really want to you can chuck it in your compost bin at home.

We have also reviewed our swing tags and where possible, reduced these by putting more information about our products online. Avoiding unnecessary tags by only attaching key information will reduce the amount of cardboard we use. Like our shoe boxes, our swing tags have also been changed to recycled card and vegetable-based inks.

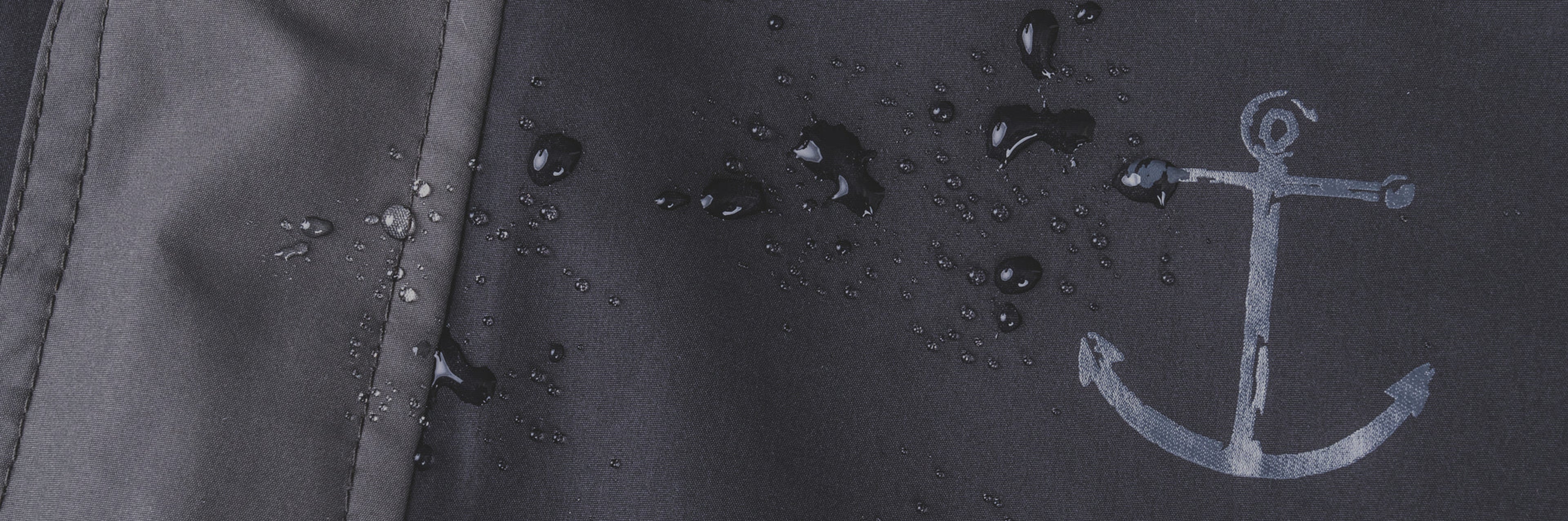

Durable water repellent (DWR) helps water to bead off our rainwear and also repels dirt, allowing our jackets and trousers to perform at the highest level. The DWRs contain perfluorinated compounds (PFCs). These chemicals are used in waterproof outdoor apparel as well as many more common household items such as nonstick cookware and paints.

Researching the types of chemicals that go into the waterproofing of our jackets and trousers is where we found some really nasty realities. While there are no health risks when using the jackets, there are significant health and safety concerns caused by the by-products in DWR production, and if these by-products are later dumped inappropriately in landfills. One particularly concerning by-product, is the highly toxic perfluorooctanoic acid (PFOA).

In the past, Evolve used the industry standard DWR called C8, which is highly effective and phenomenally durable. Unfortunately, its production results in a large amount of PFOA byproduct being created which does not decompose. Despite its high performance and that this is still being used by our competitors, the environmental and health concerns make it unacceptable for us to continue to use.

Our DWR is completely free of PFC's, PFOA's, and PFOS's. This alternative to C8 is more expensive to produce and not as effective performance wise, but in accordance with our Sustainability Promise, we will not compromise on our environmental and social responsibility. It was therefore an easy decision to adopt this as our DWR.

In 2017 we were shocked to learn the horrors of how down from the insulation of jackets was sourced. Geese and Ducks being pinned down and ripped apart for their plumage, the soft insulation under their feathers. Once plucking is complete they are left naked and bleeding without pain relief, to shiver and suffer while their feathers grow back. Some farms were found to pluck their birds up to four times a year.

We looked at ethically sourced down alternatives. First; farms that do not live-pluck, kill the birds for their meat before they are plucked for their down. This way the birds are not living in pain and suffering. The problem here is, tracing the source of the down to ensure it is cruelty free is incredibly difficult.

If the down product doesn't have a certified tag, stating it's from non live plucked sources, how do you trust it?

TRACEABILITY

Another issue is that many of the duck and geese farms are widely dispersed throughout Europe and Asia, causing it to be very difficult to monitor exactly where the down is sourced from to ensure that the farms are actually keeping their birds in reasonable living conditions. A level of skepticism is required when relying on the information being provided by the farms about their own conditions.

Through our own experience of trying to source down free from live-plucked birds, we found that it is tremendously difficult to trace the down we sourced to the specific birds or even farms. Often in the factories that were making our jackets, bags of down from live and non-live plucked birds are passed around and easily mixed up.

As hunters and fishermen, we have no problem with killing animals for food and survival, it is a part of nature, but animal torture we want no part of. In our research for an ethical source, we found that there were feather down suppliers that sold Responsible Down Standard (RDS) certified feathers. This was exactly what we were after, an independent standard that ensured a traceable supply chain that guaranteed no cruelty to the birds. What we were surprised to learn though, was that some factories offered the live-plucked or foie gras options at the same time as torture free option. We decided to stay well away from supporting any of these suppliers until we knew for sure that our down was responsibly sourced from a completely ethical source.

THE CHOICE TO USE SYNTHETIC

In 2018 we released our Hunters Element Razor Jacket and Vest with a premium synthetic down substitute and continued our search for responsible down suppliers. The synthetic option is very close to down these days and actually outperforms down when wet, but still lags behind a little bit in the weight to warmth ratio. The intention was to move back to feather down when we found a supplier that sourced the feathers as a by-product of the food industry and no animal torture was involved at any stage of the animal's life.

THE PROCESS TO GO BACK TO FEATHERS

In late 2018 our search took us to China where we found some likely candidates to be a responsible supplier. These suppliers were all fully RDS certified and claimed to not offer live-plucked or foie gras options. To know for certain, we had to see the whole process ourselves, from the birds living conditions to the killing of the birds, all the way through to how the down was cleaned and prepared. It’s fair to say that the supplier was adhering to the claims they made so we decided that we would be comfortable bringing feathers back into the range.

In 2020, we started the development of our new insulated jackets for Autumn Winter 2021, the Sleet and Glacier Jackets. We found PrimaLoft, an RDS certified performance down supplier who has developed a product that was just what we were looking for, bringing together the best of both materials. Fibres of synthetic down is blended with duck down, which allows the down clusters to maintain loftiness with increased spring back, allowing the fill to hold more heat while being incredibly light and packable. The water-resistant treated duck down and synthetic down combined outperform each element individually in heat retention, packability and performance, wet or dry.

In early 2019, CEO Rob Wilson and Head Product Designer Alex Broad jumped on a plane to see it for themselves and here’s what we saw from our responsible down supplier.

LIVING CONDITIONS

The first stop was to inspect the living conditions of our birds to ensure none were mistreated. The down we use in our jackets is a by-product of ducks farmed for Beijing (Peking) Duck, which is required to look pristine for presentation in restaurants. This was a reassuring sign that the birds we were going to be getting our down from were not mistreated. In order to have a duck that looks pristine in restaurants, it needs to be treated very well throughout its life (ie. fed well, able to develop muscles properly through exercise, no bruises or cuts, etc). A duck that lives its life in a cage or force-fed hormones to grow quickly, does not come out the other end looking good enough for Beijing Duck. The facility was indoors to protect birds from extreme heat and cold. It had opening windows for ventilation, large fans, plenty of room to wander around, food and water on tap, with absolutely no forced feeding or animal abuse.

KILLING AND PLUCKING

Next was the facility where the ducks were killed and the feathers were plucked. The ducks were killed using Halal methods, which involves a prayer being performed to pay respect to the animal before being killed humanely. The dead birds were put through a machine that instantly plucked the feathers, which were then frozen so they didn’t smell or rot while being shipped to the cleaning and drying facility. The killing method was very quick, clean and unstressful which again was very reassuring.

SELECTING AND WASHING THE FEATHERS

The magnitude of the washing, drying and seperating facitlity was quite remarkable. First the feathers are washed and dried. The feathers are then put into seperating chambers. These are four enormous tumble dryers, each one five stories high, where the feathers are mechanically fluffed repeatedly until the light down feathers float to the top and pass into the next chamber. The further along the row of chambers the feathers reach, the higher the quality and loft of the down is. This entire process can be repeated up to 10 times in order to obtain the highest quality down.

THE FINAL PRODUCT

Inspecting the entire process of our bird's lives, through to how they are killed, and plucked was comforting knowing that there was absolutely no mistreatment, force-feeding, live plucking, and the birds were killed humanely. This allowed us to check all the boxes required to go away from synthetic down and back to feather down.

The world’s going to hell in a hand-basket! Or it’s actually not that bad and people are overreacting. Whatever your spin on it, everyone should agree that recycling some trash, planting some trees, cleaning up a river and giving our animals a helping hand is well worth doing. So in conjunction with the Sustainability Promise, the fund was established to contribute additional help to the things that matter to us... the outdoor adventurers. And hopefully we can make things a little nicer out there for the next generation.

HERE'S HOW IT WORKS

By Purchasing select Evolve Outdoors you are contributing to this initiative. The primary source of money is generated from sales of marked products. A portion of revenue from these products will be fed into the fund. The money is then spent on projects that the whole team agree are well worth the investment.

The funds raised and projects will be shown right here so everyone can see where their money is going the difference they are making.

The purpose of the Leave Only Trails Fund is to raise money to invest in positive, environmental projects in our communities and give back to the wicked-cool areas that give so much to us.

SUSTAINABLE COASTLINES

A quintessential part of being a kiwi is enjoying our waterways and coastlines. Through the Leave Only Trails Fund we are proudly a sponsor for Sustainable Coastlines, a charity who enable kiwis to look after our water. They do this by hosting and providing tools for clean up events, restoring rivers through riparian planting and educating the next generation on the effects of littering.

RAIPARIAN PLANTING

New Zealand’s rivers are not in the best shape. 62% of monitored lowland rivers are not safe to swim in, even the fish have disappeared. Instead of the clean rocky river beds, we now have silt which does not support food or habitat for fish. Over the years, we cleared lowland forest to make way for settlements, farming, forestry and agricultural land. These trees provided shade, structural habitat and strength to river banks keeping the river healthy to support an abundance of life. We are supporting Wai Wanaka’s Cardrona Kaitaki project in Otago by sponsoring riparian planting through the Million Meters organisation by Sustainable Business Network.

BLUE DUCK PROJECT

We support The Blue Duck Project in the central north island and the Mangaotane Whio Conservation Project in the southern Raukumara on the East Coast, north of Gisborne, in protecting their Whio residents. This involves controlling predators along the margins of the river, particularly during the nesting and fledging season, between August and January. We have donated effective and easy maintenance A24 traps to these organisations. Through trapping, we can give the Blue ducks a chance to nest, raise their young and build up their numbers so we can see these in abundance on our rivers once again.

REPREVE

Following the immense support of our Sustainability Promise initiatives, we have continued to search for new ways to reduce our impact on the environment and shrink our carbon footprint. One issue that we want to help solve is the amount of rubbish that is polluting our waterways, forests, beaches, and landfills. We eliminated the plastic wrapping our gear and replaced it with a biodegradable card wrap, however, we wanted to take it a step further.

And we have!

We are thrilled to have be partnered with Unifi® and REPREVE®, the worlds leading recycled fiber manufacturer, since 2019 to make our technical hunting fabrics out of recycled plastic bottles. We’re ecstatic to to use REPREVE® recycled fibers and help them recycle over 20 billion plastic bottles, and counting.

HOW IT'S DONE

Step 1: Used plastic bottles are collected and cleaned.

Step 2: The clean bottles are shredded and melted into plastic chips.

Step 3: The chips enter a state of the art extrusion and texturing process and transformed into fibers.

Step 4: The fibers are knitted or woven to create the fabrics that make our high-performance outdoor gear.

THE BENEFITS

This means gear like our jackets, mid-layers, trousers and gloves will be directly reducing the amount carbon waste polluting the air, as well as removing plastic and rubbish destined for landfills. This comes at approximately 50 bottles per garment.

A huge benefit is that we’re conserving resources by finding a new life for used products. Compared to creating virgin fiber, making our recycled fabrics offsets using new petroleum, emitting fewer greenhouse gases and conserving water and energy in the process.

Once our gear has loyally served you and your adventures for years and has finally done its dash, the material can be stripped apart and turned back into the new fiber to create a whole new product.